Equipment stock

- Non-woven fabrics manufacturing machine

The line enables to manufacture the material, used as noise insulation in the automotive industry, as heat retainer for clothes, furniture filling, mattresses, thermal insulation in production, backing for flooring, geotextiles, filter materials etc.

We can produce the needle-punched and thermo bounded fabric weight 10-2000 g/m2, width up to 5 meters. Materials content is PET, PES, PP, viscose, cotton fibers. The thickness of the materials produced is 0.2 mm-100 mm, materials can be volumetric. The fabrics are made to order, in accordance with the customer's technical requirements.

2. Latex and adhesive layer application laminating line

Glue is applied on the material up to 2 meters wide. The equipment enables to duplicate various materials and apply the latex and adhesive layer to paper, fabrics, PPU, PVC-materials, foils and other rolled materials.

Duplication is performed with the help of water-resistant acrylic glue.

The applied acrylic glue is dried in a thermo chamber, after that the decorative layer and the substrate are glued under pressure of the pressing shafts on a special equipment. After duplication the materials are rolled to provide more convenient transportation, or cut into sheets.

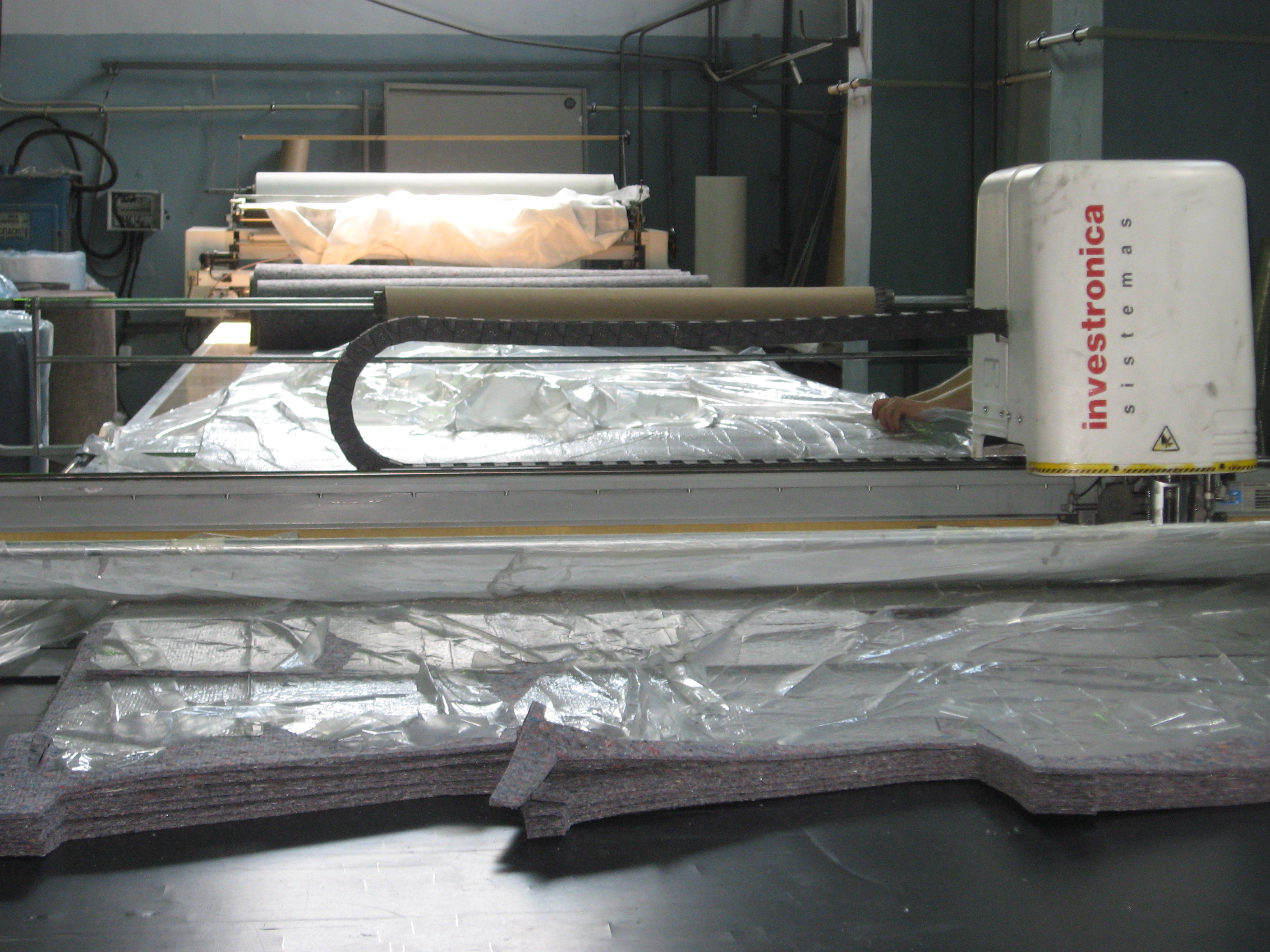

3. Automatic cutting complex

The equipment type, completed with the digital belt-moving system enables to nest-pattern any fabrics into the needed shapes, cut out the holes of the needed diameters. The possibility of simultaneous nest-pattern of several fabric layers after vacuuming provides high productivity and as a result low cost of works. Materials eligible for cutting are paper, fabrics, felts, plastic, PPU, PVC-materials, magnets, foils, etc. The automatic cutting complex can operate in the following types of production: clothes, toys, bags, hosiery goods, furniture, automotive manufacturing sites.

4. Punching equipment: direct pressure devices and grinding roller tables

The equipment makes it possible to perform the cutting of parts from carton, fabrics, felts, foamed materials, PVC materials, etc. The tooling is developed in accordance with the customer drawings, needed shape part punching is performed on it. The possibility to combine kiss-cutting, perforation, joint forming, blind embossment exist. These presses are supposed to work in the production sites, dealing with productions making components for the automotive industry, mechanic engineering, furniture and stitching industry, construction industry.

5. Punch-emboss rolling machine

The machine is intended for kiss-cutting and hot embossment of various rolled materials: self-adhesive materials, paper, fabric, felts, plastic, foamed materials, EPDM, PVC-materials, magnets, foils, etc.

Our kiss-cutting machine is equipped with the adhesive, punch and emboss joints, what results in simultaneous performance of several operations at high speed, finally we receive rolled material with self-adhesive kiss-cut parts. Materials eligible for kiss-cutting: paper, fabrics, felts, plastic, foamed materials, EPDM, PVC-materials, magnets, foils, films, etc. The finished goods can be applied as self-adhesive paddings and sealing parts for furniture, doors, windows, household goods, electrical appliance, transport means.

6. Full-stage safety flooring production line

The equipment makes it possible to produce PVC safety flooring of the well-known brands Translin Auto and Translin Autolux (analogues of popular Polyflor and Altra). The material is produced by means of duplicating decorative PVC layer with non-woven and cellulose paper with corresponding scattering of aluminum carbide and other anti-sliding particles and embossment. The equipment manufactures both commercial and household flooring.